Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

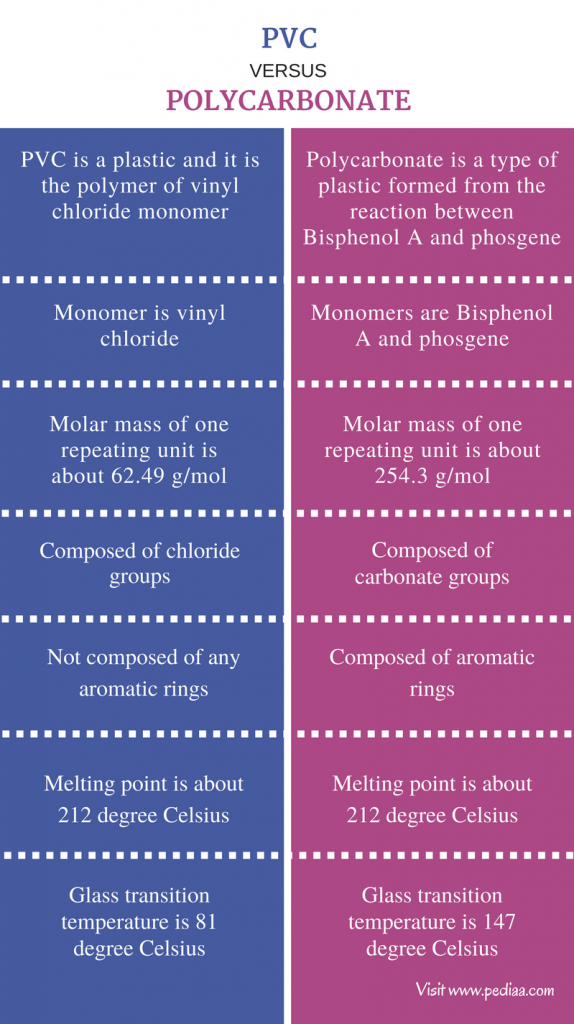

Lexan PC sheet, also called polycarbonate sheet, is an engineering plastic with excellent overall performance. PVC or Vinyl is the abbreviation of polyvinyl chloride, which is a polymer made by the polymerization of vinyl chloride monomer under the action of peroxide, azo compounds and other initiators; or by the mechanism of free radical polymerization reaction under the action of light and heat. Vinyl chloride homopolymers and vinyl chloride copolymers are collectively called vinyl chloride resins.

PVC is the abbreviation of polyvinyl chloride, which is a polymer made by polymerization of vinyl chloride monomer under the action of initiators such as peroxides and azo compounds, or by free radical polymerization reaction mechanism under the action of light or heat. Vinyl chloride homopolymer and vinyl chloride copolymer are collectively called vinyl chloride resin. vinyl is currently the second most produced general-purpose plastic and the most widely used plastic, PVC itself is also a colorless and transparent hard material, but it is much more brittle than PC, and its transparency is not as good as PC, and its other mechanical properties are also very different from PC. The so-called hard PVC is the PVC plasticizer added to 100 kg of PVC resin powder less than 5 kg of PVC plastic plastic, such as construction pipes, downspouts, plastic windows, credit cards and so are hard PVC. plasticizer added more than 5 kg is called semi-hard PVC, more than 25 kg is called soft PVC.

One of the major applications of vinyl in life is wall stickers.

You can find them everywhere online. The peel & stick vinyl wall decal is a smooth, satin finished product that is easy to install and totally removable! The vinyl wall material is also adjustable, featuring air-release channels allowing air to escape, resulting in a lower occurrence of air bubbles. The vinyl material is also adjustable, featuring air-release channels allowing air to escape, resulting in a lower occurrence of air bubbles, making it the preferred vinyl decal materials for wrapping vehicles such as cars, trucks, boats, and trailers. The vinyl material is available in either a glossy or matte scratch, uv, and water Transform your home or business with a custom wall decal. We found this wall stickers maker has the most various selection of the stickers used in life. Make a personal logo, quote or family portrait come to life with a wall decal. Easy to apply and you won’t be left with any sticky residue behind. Custom wall decals can make any space stand out and look professional. PVC can also be colored at will and made into various transparent and opaque colored products, so PVC is the most versatile plastic at present, and the price is only about 1/2 to 1/4 of PC.

The outstanding advantages of PVC products are its incombustibility, abrasion resistance, chemical resistance, and low leakage of gas and water vapor. In addition, the comprehensive mechanical properties, product transparency, electrical insulation, heat insulation, muffling, shock absorption, is the most superior performance to price ratio of general-purpose materials. The disadvantage is that the thermal stability and impact resistance are poor, and both hard and soft PVC are easy to produce brittleness in the process of use; PVC is most commonly used and cheap.

Lexan is Polycarbonate, a colorless, transparent, unqualified thermoplastic material. Known as a transparent alloy with very high mechanical strength, polycarbonate is colorless, transparent, heat resistant, impact resistant, flame retardant, and has UL94 V-0 grade flame retardant properties without additives. Because of its colorless transparency and excellent impact resistance, common daily applications include optical discs, resin eyeglass lenses, mugs, kitchenware (juicers, etc.), bulletproof glass, goggles, headlights, etc. PC is only available in rigid. PC is only available in rigid form. PC sheet is a high quality bar material made of polycarbonate as the main component using co-extrusion technology. Because its surface is covered with a high concentration of ultraviolet absorbers, in addition to its anti-UV characteristics and can maintain long-term weathering, never fade. Polycarbonate has high strength, high impact toughness, high glass transition temperature, and heat resistance, PC material working temperature between -60 ℃ to 120 ℃. It is a high-tech, extremely excellent overall performance, energy-saving and environmentally friendly plastic sheet, and is a commonly used plastic building material internationally.

PC sheet is the king of transparent plastics and is an engineering plastic with exceptionally good performance. pc sheet is basically indestructible and can bear great force. pc sheet is easy to be processed for finishing. All kinds of paints and lacquers can be evenly coated on the density board, which is the base material for doing the painting effect. A variety of veneer panels, films, decals and other materials can be glued on the surface of PC board. The impact strength is still very high, and the scale stability performance is good, but also colorless and lucid, coloring performance is also good, electrical insulation as well as corrosion resistance, wear resistance is good. Such excellent properties also lead to the expensive price of PC, but the strength is high and the time spent is relatively long.

Plastics are plastic (flexible) materials that are formed by processing with high molecular weight synthetic resin/petroleum as the main component and adding appropriate additives, such as plasticizers, stabilizers, antioxidants, flame retardants, lubricants, colorants, etc., or rigid materials formed by curing and cross-linking.

Plastic waste is difficult to decompose naturally, and if it flows into the ocean, it can lead to marine life accidentally eaten, suffocation, poisoning, etc., affecting marine ecology; incineration of plastic waste can also cause air pollution, polyvinyl chloride (PVC) and polycarbonate (Polycarbonates) and other plastics, even under certain conditions will release harmful substances or endocrine disruptors, endangering biological reproductive function.

So, what types of plastics are there? What are their uses? Academic has summarized some common and special plastics for readers’ reference.

Polyethylene terephthalate (PET): beverage bottles, films, packaging.

Polypropylene (PP): food packaging, household appliances, auto parts (such as bumper).

Polypropylene (Polypropylene, PP): food packaging, household appliances, auto parts (such as bumpers).

Polystyrene (Polystyrene, PS): packaging materials, food packaging, disposable cups, plates, tableware, CD and DVD folders.

High impact polystyrene (HIPS): packaging materials, disposable cups.

ABS resin / acrylonitrile butadiene styrene copolymer (Acrylonitrile butadiene styrene, ABS): covering electronic equipment (such as monitors, printers, keyboards).

Polyester (Polyester, PES): fibers, textiles.

Polyamide (Polyamides, PA): fiber production, golf balls, fishing line, automotive coatings.

Polyvinyl chloride (Polyvinyl chloride, PVC): pipe production, shower curtains, window frames and floor coverings.

Polyurethane (Polyurethanes, PU): foam insulation, fire prevention, fire fighting foam.

Polycarbonate (Polycarbonate, PC): optical discs, sunglasses, protective shields, safety glasses, indicators, lenses.

Polyvinyl chloride (Polyvinylidene chloride, PVDC): packaging (such as food and medicine).

Polyethylene (Polyethylene, PE): film, bags (generally common plastic bags), filling bottles (such as shower gel, detergent), water pipes.

Polycarbonate / ABS resin (Polycarbonate/Acrylonitrile Butadiene Styrene, PC/ABS): a combination of PC and ABS plastic, more robust, used for automotive interiors and exterior accessories, cell phone cases.

Polymethyl methacrylate (PMMA): contact lenses, glass (such as Plexiglass).

Polytetrafluoroethylene (Polytetrafluoroethylene, PTFE): heat-resistant, low-friction coating: non-stick coating of non-stick pans, sealing tape for plumbers, water slides for playgrounds, etc.

Polyetheretherketone (Polyetheretherketone, PEEK): chemical and heat-resistant thermoplastics, high biocompatibility, use medical implants, aerospace products.

Polyetherimide (PEI): High temperature resistant, chemically stable, non-crystalline polymer.

Phenolics (PF): commonly known as Bakelite, high modulus, relatively heat resistant, fire resistant and excellent polymers. Used for electrical equipment insulation parts, paper laminated products, thermal insulation foam materials.

Urea-formaldehyde resin (Urea-formaldehyde, UF): tableware, decorations, electrical parts, power distribution apparatus, telephone tubes, automobile parts, plywood, adhesives, coatings, buttons, containers, mahjong tiles, clockwork plates, chopsticks, clothespins, bottle caps, etc.

Melamine formaldehyde resin (MF): glass, tableware, decorations, electrical parts and shells, switchboards, mechanical parts, automobile parts, lamplight panels, coatings, adhesives, containers, paper, resin processing of cloth.

Polylactic acid (PLA): one can be decomposed by microorganisms and transformed by corn starch. Currently commercially available, such as the clear box for water-selected eggs.

Although plastic has become an indispensable necessity for human life, in order to solve the problem of white pollution and protect the land and sea on which human beings depend, human beings not only need to further strengthen environmental awareness, but also need to use the power of science and technology to deal with plastic waste in a greener way, as well as to create more green alternatives to plastic.

In this video, you’ll discover the 7 most common types of plastic. What are their advantages and which type of plastic is most suitable for your product?